CYLINDER & GEAR BOX Casting Parts Supplier: High-Quality and Affordable Options for Your Business

A reliable supplier of casting parts is essential to the manufacturing industry, and CYLINDER & GEAR BOX is one such supplier. With years of experience in the field, they have established themselves as a trusted source for high-quality casting parts. Their commitment to providing excellent customer service and timely delivery has made them a go-to choice for many manufacturers.

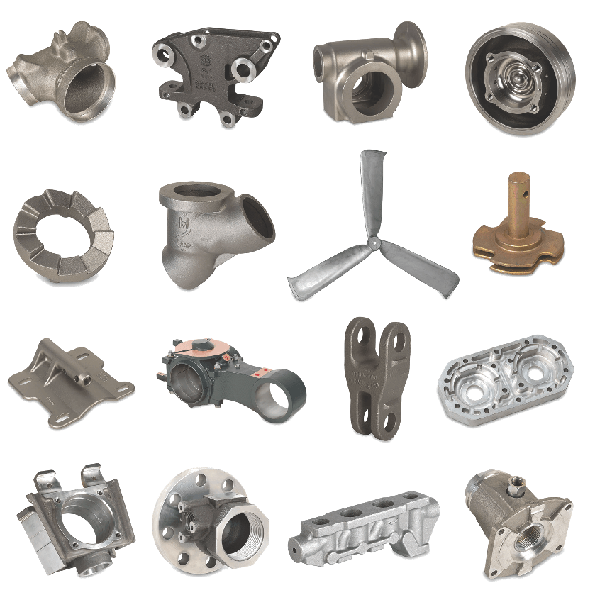

CYLINDER & GEAR BOX specializes in producing a wide range of casting parts, including cylinder heads, engine blocks, and gearboxes. They use advanced technology and high-quality materials to ensure that their products meet the highest standards of quality and durability. Their team of skilled engineers and technicians work closely with clients to ensure that their specific needs are met, and that the final product is tailored to their unique requirements.

With a focus on quality, reliability, and customer service, CYLINDER & GEAR BOX is a leading supplier of casting parts to the manufacturing industry. Their commitment to excellence has earned them a reputation as a trusted partner for many manufacturers, and their dedication to meeting the specific needs of each client sets them apart from the competition.

Cylinder Casting Parts

Cylinder casting parts are essential components in the manufacturing of various industrial products, including engines, compressors, pumps, and other machinery. These parts are commonly made from materials such as aluminum, iron, and steel, depending on the application.

Cylinder casting parts are typically used in internal combustion engines, hydraulic systems, and pneumatic systems. They are responsible for housing pistons and providing a sealed chamber for the compression and combustion of fuel. Cylinder heads, cylinder blocks, and cylinder liners are common cylinder casting parts.

When it comes to choosing a cylinder casting parts supplier, quality should be a top priority. A reputable supplier should be able to provide consistent quality parts that meet or exceed industry standards. They should also have a proven track record of delivering on time and providing excellent customer service.

In addition to quality, it is also important to consider the supplier’s capabilities. A good supplier should have the expertise and resources to provide customized solutions that meet the specific needs of their customers. They should also be able to offer a wide range of cylinder casting parts, including different sizes, shapes, and materials.

Overall, choosing the right cylinder casting parts supplier can make a significant difference in the performance and reliability of industrial machinery. By working with a trusted supplier, manufacturers can ensure that they have access to high-quality parts that meet their exact specifications.

Gear Box Casting Parts

When it comes to gear box casting parts, it’s important to find a supplier that offers high-quality parts that are durable and reliable. There are a variety of factors to consider when choosing a supplier, including the materials used, the manufacturing process, and the quality control measures in place.

Gear box casting parts are integral to the functioning of gearboxes, which are mechanical devices used to transmit power and torque from an input shaft to an output shaft at a specific speed ratio. Gearbox casting parts include housing, covers, gears, shafts, and bearing supports. These components are crucial for ensuring smooth gear shifting and efficient power transmission.

One of the key benefits of choosing a reputable gear box casting parts supplier is the ability to customize parts to meet specific needs. This can include selecting the appropriate materials, such as aluminum, iron, or steel, and ensuring that the parts are designed to withstand the specific stresses and pressures of the gear box.

In addition to customization, it’s also important to choose a supplier that has a proven track record of producing high-quality parts. This can be achieved by looking for suppliers that have certifications or accreditations, such as ISO 9001, which demonstrate a commitment to quality and continuous improvement.

Overall, when choosing a gear box casting parts supplier, it’s important to consider factors such as customization, quality, and reliability. By doing so, you can ensure that you are getting the best possible parts for your gear box needs.

The casting process for both cylinder and gear box parts typically involves the following steps:

- Pattern Creation: A pattern, which is a replica of the desired part, is created using wood, metal, or plastic.

- Mold Preparation: The pattern is used to create a mold, which can be made of sand, ceramic, or other materials. The mold is made in two halves, the cope, and the drag.

- Molten Metal Preparation: The metal or alloy used for casting, such as iron, aluminum, or steel, is melted in a furnace at high temperatures.

- Pouring: The molten metal is poured into the mold cavity through a gating system, which allows the metal to flow smoothly and fill the entire mold.

- Solidification: The molten metal cools and solidifies inside the mold, taking the shape of the pattern.

- Shakeout and Finishing: Once the metal has solidified, the mold is broken to remove the casting. The casting is then cleaned, excess material is removed, and finishing operations like grinding, machining, and surface treatment may be applied.

- Quality Assurance: The casting is inspected for any defects, such as porosity, cracks, or dimensional inaccuracies. Non-destructive testing methods like X-ray or ultrasonic inspection may be employed to ensure the quality of the parts.

- Machining and Assembly: After inspection, the casting may undergo further machining operations to achieve the required dimensions and surface finish. The parts are then assembled into the final product, such as an engine or a gearbox.

It’s worth noting that the specific casting process and materials used can vary depending on the requirements of the part, industry standards, and the manufacturer’s capabilities.

Casting Parts Supplier

When it comes to sourcing quality casting parts for cylinders and gearboxes, finding the right supplier is crucial. Hengke Metal can provide high-quality parts at competitive prices and offer excellent customer service. Here is some information about a reputable supplier of cylinder and gearbox casting parts.

Hengke Metal is a leading manufacturer and supplier of casting parts for cylinders and gearboxes. They have been in the industry for many years and have a proven track record of delivering high-quality parts to their customers. They offer a wide range of casting parts, including cylinder heads, engine blocks, gearboxes, and more.

One of the key advantages of this supplier is its state-of-the-art manufacturing facilities. They use the latest technology and equipment to produce casting parts that meet or exceed industry standards. Their skilled technicians and engineers ensure that each part is thoroughly inspected and tested before it is shipped to the customer.

In addition to their high-quality products, this supplier is also known for their exceptional customer service. They have a team of knowledgeable and experienced professionals who are always ready to assist customers with their needs. They offer flexible payment options, fast delivery, and hassle-free returns.

Overall, if you are looking for a reliable supplier of cylinder and gearbox casting parts, this supplier is a great choice. They offer high-quality products, competitive prices, and excellent customer service.